Socks Factory

Sock Production Department at Our Company: Unmatched Quality and Professionalism

The sock production department at our company stands at the forefront of our manufacturing operations, combining advanced technologies and extensive expertise to deliver products of unparalleled quality. We are committed to providing socks that meet customer expectations while achieving the highest standards of comfort, durability, and style. From design to final production, we pay close attention to every small detail that makes a big difference.

Sock Manufacturing Process – Quality and Excellence Standards

- Expert Design and Development

The process begins with creativity, where our design team integrates the latest fashion trends with customer needs, using modern tools and technologies to create 3D models that showcase every detail of the sock, ensuring both comfort and aesthetic appeal. During this stage, every detail is meticulously considered, from the overall design to the selection of colors and textures.. - Careful Raw Material Selection

Quality starts with the raw material. We carefully select a wide range of materials such as cotton, natural wool, and antibacterial fibers to ensure outstanding quality. We also conduct rigorous tests to ensure that the materials meet our strict standards and are both safe and environmentally friendly.. - Advanced Knitting Techniques

Using the latest computerized knitting machines, the basic fabric of each sock is produced according to a precise design. The machines can be programmed to meet the specific requirements of each sock type, whether athletic, formal, or medical, ensuring that the final product fulfills its intended function. This technology allows us to maintain a consistent level of quality throughout the production process.. - Precision Shaping and Professional Cutting

At this stage, the socks are shaped and cut according to standard measurements. The company uses advanced equipment that ensures cutting accuracy while preserving the details of each design. Every sock is reviewed to ensure uniformity and style, confirming it aligns with the approved initial designs.. - Finishing and Quality Control Standards

We don’t just produce socks; we care about the finishing touches that enhance their appeal and comfortable texture. After finishing, the socks undergo strict quality control inspections, which include tests for colorfastness, fiber elasticity, and stitching durability to ensure that each pair meets the highest standards of quality before reaching our customers..

Types of Socks – A Variety to Meet All Needs

At our company, we understand that customers seek variety, so we offer a comprehensive range of socks that includes::

- Athletic Socks: Designed with advanced moisture-wicking technology and support features, using special materials to ensure maximum comfort for athletes..

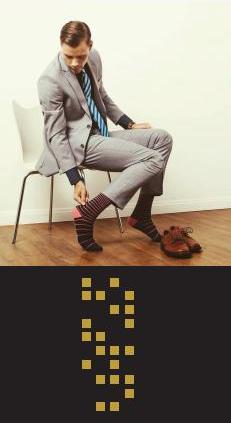

- Formal Socks: Suitable for all formal occasions, crafted with elegance and high-quality materials that offer comfort throughout the day..

- Children’s Socks: Made from soft and skin-friendly materials, featuring colorful and attractive designs that appeal to a variety of children’s tastes..

- Medical Socks: Designed with compression features to support blood circulation, making them ideal for individuals with health issues..

Innovation and Sustainability – Towards Eco-Friendly Production

We are committed to sustainable practices, working hard to minimize material and energy waste, with a focus on recycling certain materials and reducing our environmental footprint. Using eco-friendly production techniques, we deliver world-class socks without harming the environment, ensuring that each step of the production process contributes to efforts to preserve our planet..

Our company continuously strives to be synonymous with quality and innovation in the sock manufacturing industry, with customer comfort and satisfaction at the core of everything we deliver..