Knitting Factory

The Core Process at Our Factory: Manufacturing High-Quality Knitwear Garments At our factory, the manufacturing process involves several crucial stages designed to produce garments that guarantee the highest standards of quality.

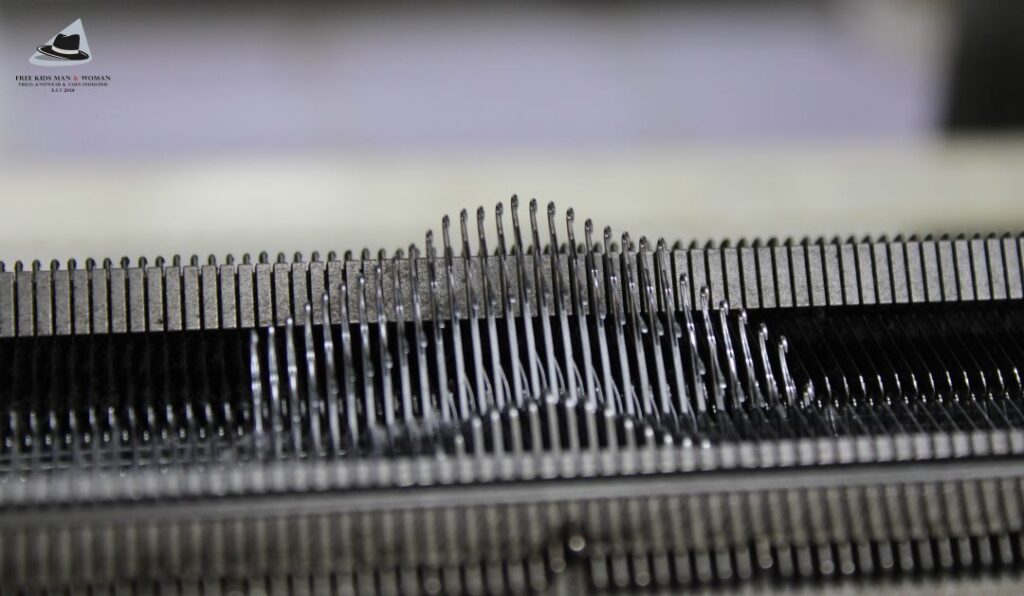

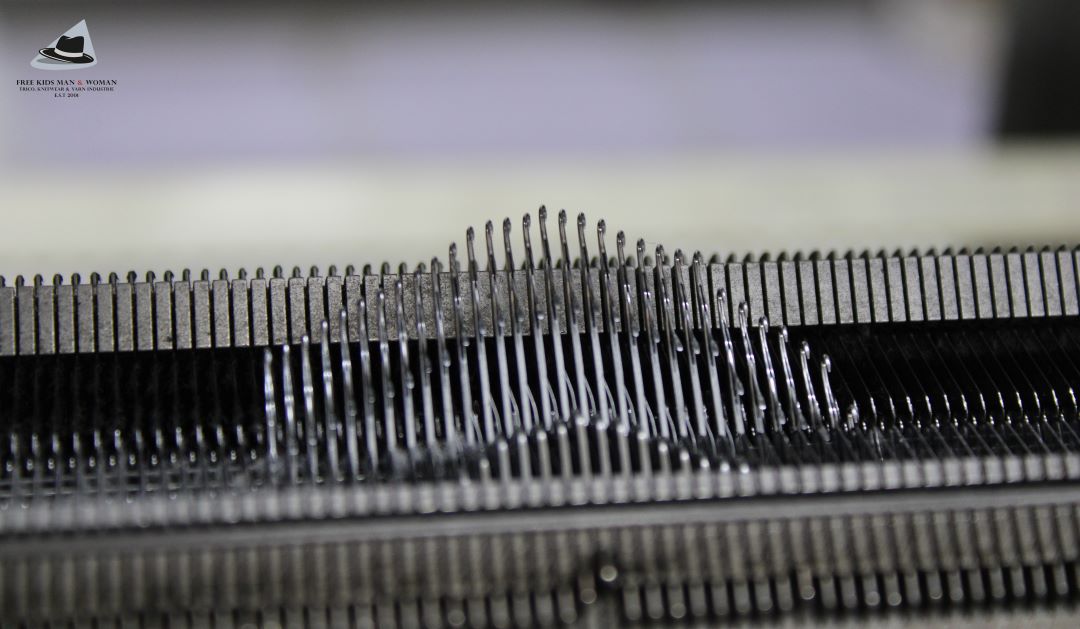

Knitting Stage in Our Knitwear Factory

In the Free Kids Man & Woman factory, the knitting stage is the heart of the knitwear sweater manufacturing process. We take pride in having a team of skilled artisans with extensive experience in advanced knitting techniques, ensuring that we deliver high-quality products that meet our customers' expectations.

Steps in the Knitting Process:

- Preparation and Setup:

- First, we carefully prepare the raw materials by selecting the finest wool, cotton, and other premium fibers to ensure both durability and a great final appearance.

- We also set up the necessary machinery and equipment, using the latest knitting machines to guarantee precision and quality in the work.

- Pattern Selection:

- The desired design for each sweater is chosen, with the team using various knitting techniques to produce specific patterns, such as straight knitting or more complex designs, facilitated by professional designers in the design rooms.

- Knitting Process:

- The artisans begin the knitting process, carefully operating the machines to form the fabric according to the desired design. Special attention is given to details, such as the edges and finishing touches, to ensure a professional-looking final product.

- Quality is monitored at every step, with the quality control team inspecting each piece during the knitting process to ensure no defects.

- Finishing Touches:

- Once the knitting process is complete, finishing touches are applied, such as cutting excess threads and adjusting sections to ensure a perfect fit.

- Special techniques are used to enhance the fabric's quality, making it softer and more comfortable to wear.

- Quality Testing:

- Before sending the sweaters for sewing, a comprehensive test is conducted to ensure each piece meets our high-quality standards. We believe every piece should reflect our craftsmanship and commitment to quality.

Our Commitment to Quality:

We believe the knitting stage is one of the most important steps in sweater manufacturing. That’s why we ensure every team member is committed to the highest standards of craftsmanship and precision. Thanks to this dedication, we can offer sweaters that are both high-quality and stylish, meeting our customers' expectations.

This unique process makes our knitwear sweaters the perfect choice for those who seek both style and comfort in every season!

Cutting Stage in Our Factory

The cutting stage is a vital step in manufacturing knitwear sweaters in our factory.

Steps in the Cutting Process:

- Preparation: Patterns and designs are prepared using modern design software to ensure accuracy.

- Cutting Process: Advanced machines are used to cut the knitwear precisely, with a focus on minimizing waste.

- Quality Inspection: The pieces are inspected to ensure they are free from defects before moving on to the knitting stage.

Our Commitment to Quality:

At Free Kids Man & Woman, we ensure the production of precisely designed and high-quality knitwear sweaters, paying attention to every detail.

Sewing and Accessory Installation Stage in Our Factory

The sewing and accessory installation stage is one of the key processes in manufacturing knitwear sweaters at Free Kids Man & Woman, contributing to ensuring a high-quality product with a professional finish.

Steps in the Sewing Process:

- Machine Sewing:

- The sewing process starts with the use of modern, advanced machines, guaranteeing precision in assembling the sweater's parts. The different parts are sewn with great care to ensure no defects in fit or finishing.

- Accessory Installation:

- After the basic sewing process, accessories such as zippers and buttons are added. These accessories are carefully selected to match the sweater design, ensuring they function efficiently without issues.

- Hand Sewing:

- Hand sewing is applied to fine details such as sleeve hems and collars, ensuring the highest quality standards. Skilled artisans ensure these details are meticulously crafted and organized, reflecting the professionalism in our work.

- Final Finishing:

- Once sewing and accessory installation are complete, a thorough inspection is carried out to ensure every piece meets our quality standards. We check for any flaws in sewing or accessories.

- Final Finishing:

- The final finishing process includes trimming excess threads, adjusting the dimensions, and ensuring the sweaters are ready for release. The sweaters receive final touches that enhance their appearance and increase their attractiveness.

Our Commitment to Quality:

At Free Kids Man & Woman, we consider the sewing and accessory installation stage essential to ensure our knitwear sweaters reflect the highest standards of quality and elegance. We are committed to delivering products characterized by precision and attention to detail, making each sweater unique.

This stage is vital to achieving a professional design, making our jackets the perfect choice for anyone seeking elegance and comfort!

Washing, Drying, and Ironing Stage in Our Knitwear Factory

The washing, drying, and ironing stage is one of the final key steps in the process of manufacturing knitwear sweaters at Free Kids Man & Woman. This stage ensures the final product is clean, comfortable, and precise in its measurements.

Sewing Process Steps:

- Machine Sewing:

- The sewing process begins with the use of modern, advanced machines, ensuring high precision in assembling the jacket components. The different parts are sewn accurately to ensure there are no defects in alignment or finishing.

- Accessory Installation:

- After completing the basic sewing, accessories such as zippers and buttons are installed. These accessories are carefully selected to match the jacket's design and are installed in a way that ensures they function efficiently and without issues.

- Hand Sewing:

- Hand sewing is used for certain fine details, such as sleeve hems and collars, to ensure the highest quality standards. Skilled artisans ensure that these details are crafted neatly and orderly, reflecting professionalism in the work.

- Quality Inspection:

- After sewing and accessory installation, a thorough inspection is carried out to ensure that each piece meets the required quality standards. The inspection ensures there are no defects in the sewing or accessories.

- Final Finishing:

- The final finishing process involves trimming excess threads, adjusting dimensions, and ensuring the jackets are ready for release. Final touches are applied to improve the appearance and enhance the jacket's appeal.

Our Commitment to Quality:

At Free Kids Man & Woman factory, we consider the sewing and accessory installation stage essential to ensuring we deliver knitwear jackets that reflect the highest standards of quality and style. We are committed to providing products characterized by precision and attention to detail, making each jacket unique.

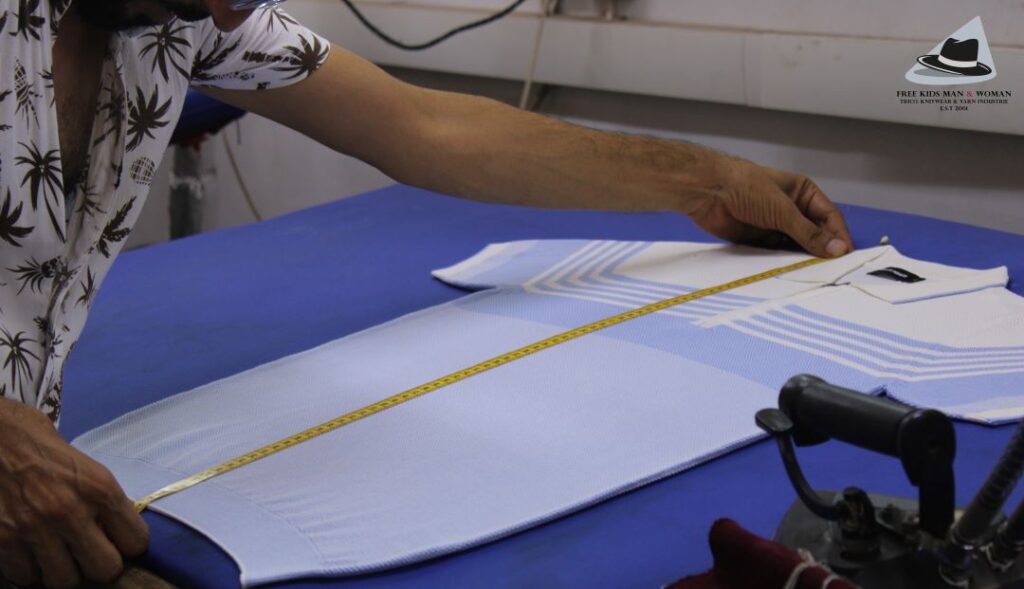

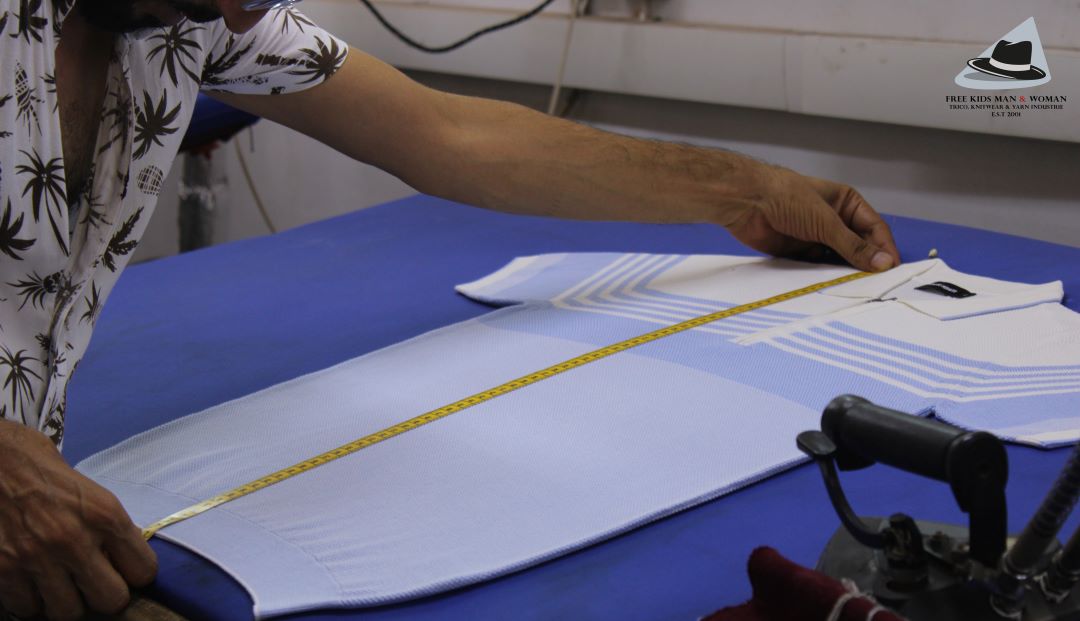

Washing, Drying, and Ironing Stage at Our Knitwear Factory:

The washing, drying, and ironing stage is a crucial final step in the knitwear jacket manufacturing process at Free Kids Man & Woman. This stage ensures that the final product is clean, comfortable, and accurately sized.

Steps in the Washing, Drying, and Ironing Process:

- Washing:

- The process begins with washing the jackets using specialized materials designed to preserve fabric quality. These materials ensure the removal of any impurities or residues from the manufacturing process without affecting the fabric's properties.

- Drying:

- After washing, the jackets are dried using advanced drying machines. This process effectively removes moisture, preserving the fabric’s shape and preventing wrinkles.

- Ironing:

- The jackets are then ironed using high-quality pressing machines and skilled technicians to ensure a neat and tidy appearance. The focus is on removing any remaining wrinkles and restoring the jacket to its perfect shape, contributing to the final product's quality.

- Size Verification:

- After ironing, the final measurements of each jacket are verified to ensure accuracy and compliance with the set standards. The quality team inspects each item to guarantee it meets customer expectations in terms of fit and appearance.

- Final Quality Check:

- The quality team performs a comprehensive inspection to ensure there are no defects in the final product. This includes reviewing details like stitching, fittings, and confirming that every jacket meets the highest quality standards.

Our Commitment to Quality:

At Free Kids Man & Woman, we consider the washing, drying, and ironing stage one of the most important to ensure that we deliver knitwear jackets of the highest quality and style. We are committed to providing products that guarantee comfort and an ideal fit, making each jacket unique and trustworthy.

Packaging and Shipping Preparation Stage at Our Knitwear Factory:

The packaging and shipping preparation stage is a vital step in ensuring that knitwear jackets from Free Kids Man & Woman reach our customers in excellent condition with an attractive appearance. This stage is carried out with meticulous care to guarantee product quality and customer satisfaction.

Steps in the Packaging and Shipping Preparation Process:

- Final Inspection:

- Before packaging, the quality team performs a final inspection of the jackets to ensure they are free from defects. Each piece is reviewed to ensure all standards and specifications have been met.

- Packaging:

- The jackets are carefully wrapped using high-quality packaging materials. Reusable bags or custom boxes are used to preserve the shape and quality during transportation.

- Labeling Information:

- Labels are attached to each package with important details such as jacket size, product number, and care instructions. This helps facilitate product identification by customers.

- Accessory Installation:

- The packages are assembled into large boxes ready for shipment. The boxes are organized in a manner that ensures their safety during transport and minimizes the chances of damage.

- Shipping Verification:

- After packaging is complete, shipping schedules are verified, and everything is checked for dispatch. This includes confirming addresses and delivery dates.

Our Commitment to Quality:

At Free Kids Man & Woman, we consider the packaging and shipping preparation stage an essential part of the knitwear jacket manufacturing process. We are committed to ensuring that our products reach our customers in the best possible condition, reflecting the professionalism and quality that we uphold at every stage of production.